Ketua Polis Bahagian Bandar Sultan Suleiman Port Klang

Kedudukan pertukaran switch over hendaklah dilaraskan secara sedikit demi sedikit bagi mendapatkan bacaan yang berkesan. Ad We Have A Large Selection Of Materials And Colors To Choose From.

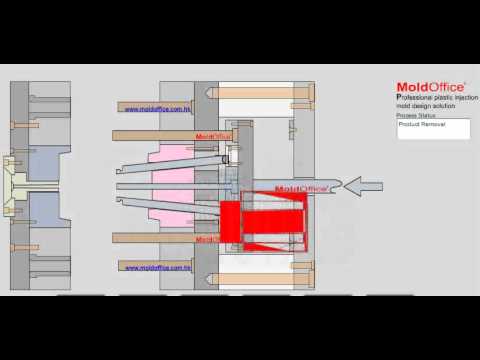

Solving Gating Problems In Injection Molding

The machine works to exert pressure and secure the mould in place during the injection.

Kaedah switch over in injection moulding. The injection molding process. An injection moulding machine consists of a material hopper a plunger and a heating barrel. Injection molding machines are typically referred to by the tonnage of the clamping force they provide.

A change in one or more variables in the molding operation can affect the whole process. Adjust the injection cylinder temperatures. The mold changing system is equipped with the control unit of the injection molding machine.

Whether the part should be run with the gate sealed frozen. Molten plastic that heated in barrel section is injected at high pressure into a. Ad We Have A Large Selection Of Materials And Colors To Choose From.

The injection molding machine employed in this study was an Arburg Allrounder 420C Arburg GmbH Lossburg Germany equipped with Mucell capability and a screw diameter of 40 mm. The required clamping force is determined by the projected area of the part and the pressure with. The melting temperature is too high or too low.

Injection molding machine 1. In Scientific Molding we determine four and there is a procedure for each. Proses ini dikenali sebagai short-shot technique.

Injection Molding SIZING AN INJECTION MOLDING MACHINE Packing pressure 108Pa Clamping force F PA Figure 7. They are all interrelated variables. Time pressure and temperature.

Adjust the screw speed to get the correct surface speed. Clamping force as a function of surface area. How to switch over from first to second stage.

Goals can be set to reduce changeover times. A larger tonnage injection molding machine could require 30 to 60 minutes for a mold change but some companies can even do this in minutes. It has the same control logic visualization and ergonomics which simplifies use and allows for the automatic.

21 Injection Molding Injection molding is a manufacturing technique for making parts from thermoplastic material.

0 komentar: